Stadium Maintenance

Stadium Maintenance: The Role of Rope Access in Overcoming Height and Structural Challenges

Stadium maintenance for venues across the UK, involves some of the most intricate and expansive structures in contemporary architecture seen today, acting as stages for sports, concerts, and major public events. Upholding these vast facilities presents a considerable challenge for stadium ownders, particularly concerning their height and structural complexities. Conventional maintenance methods typically necessitate scaffolding, cranes, or aerial lifts, which can be expensive, labor-intensive, and disruptive.

One of the most efficient solutions to these challenges is rope access —allowing workers to reach difficult-to-access areas safely and efficiently. This method is gaining popularity in stadium maintenance due to its cost-effectiveness, flexibility, and minimal disruption to operations.

In this article, we’ll explore the unique maintenance challenges stadiums face and how Dangle provides an optimal solution using roped access.

Challenges to Stadium Maintenance

The Complexity of Stadium Structures

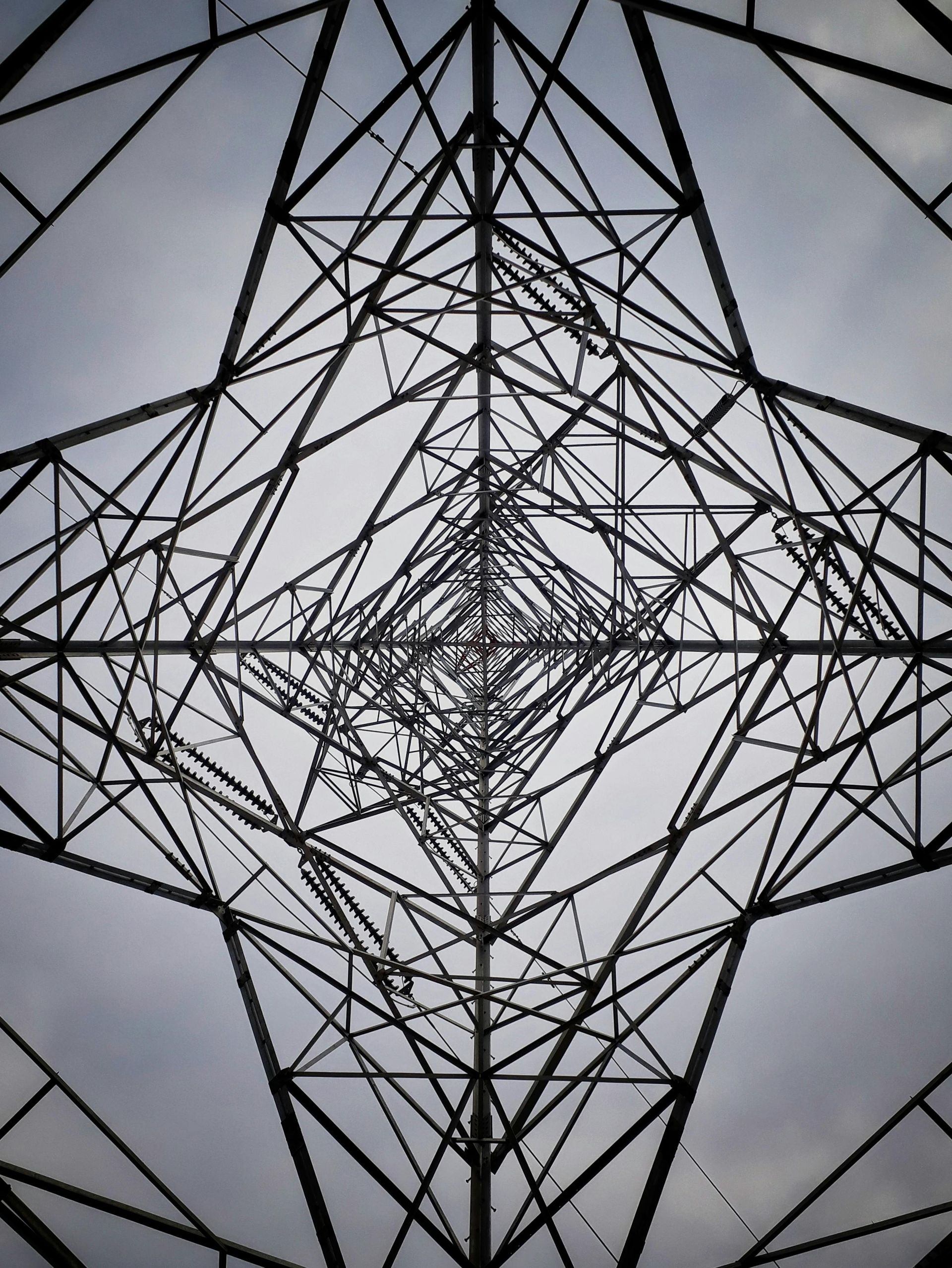

Stadiums are complex structures, characterised by vast seating areas, towering roofs, intricate facades, and large steel frameworks. The sheer scale of these elements creates significant maintenance challenges. Many components, such as lighting systems, signage, and ventilation ducts, are located at great heights, making them difficult to reach using conventional methods. Additionally, modern stadium designs often feature curved or cantilevered elements, which complicate the placement of scaffolding or aerial lifts. Structural sensitivity is another factor, as certain materials—such as glass panels and lightweight roofing—require careful handling to avoid damage during maintenance.

Safety Considerations

Beyond structural complexity, safety is a primary concern when performing maintenance at extreme heights. Traditional access solutions, such as scaffolding and aerial platforms, come with inherent risks. Erecting and dismantling scaffolding is labour-intensive and increases the potential for falls, while aerial lifts and cranes can be hazardous in high winds and adverse weather conditions. In many stadiums, space constraints further limit the feasibility of large machinery, restricting access to critical maintenance points.

Cost and Time Constraints

Cost and time constraints also play a significant role in stadium maintenance planning. Because these venues frequently host major events, any maintenance work must be conducted efficiently to minimise downtime. Traditional methods often involve high costs due to equipment rentals, labour-intensive setups, and lengthy execution times. The need for extensive scaffolding or heavy equipment can also interfere with scheduled games and concerts, resulting in revenue losses for stadium operators. Given these challenges, more stadium managers are adopting rope access as an efficient scaffolding alternative.

To address these challenges, stadium owners and facility managers are increasingly turning to rope access techniques for efficient and cost-effective stadium maintenance.

Rope Access for Stadium Maintenance

Enhanced Safety

One of the biggest advantages of rope access is its enhanced safety. Unlike scaffolding, which requires extensive assembly and dismantling, or cranes, which can be unstable in poor weather conditions, rope access provides a controlled and secure way to work at height. The use of dual-rope systems ensures redundancy, significantly reducing the risk of falls. Additionally, rope access technicians undergo rigorous certification and rope access training in safety procedures, including rescue operations and hazard mitigation. Because this method does not place excessive weight or pressure on stadium structures, it minimises the risk of damage, making it ideal for maintaining sensitive materials like glass and lightweight roofing.

Cost-Effectiveness

Cost-effectiveness is another major benefit of rope access. Traditional stadium maintenance solutions often require expensive scaffolding rentals, large machinery, and a sizeable workforce, all of which contribute to high operational costs. In contrast, rope access eliminates the need for heavy equipment and reduces labour costs, as a smaller, highly skilled team can complete tasks more efficiently. The quick installation and removal of rope systems further reduce expenses associated with setup and dismantling.

Minimal Disruption to Stadium Operations

Minimal disruption to stadium operations is a critical factor in choosing a stadium maintenance method, and rope access excels in this regard. Because it requires less setup time than scaffolding or aerial lifts, it allows maintenance tasks to be carried out quickly and discreetly. Stadiums with tight schedules can benefit from the flexibility of rope access, as work can be conducted during off-peak hours or between events. Since technicians work from ropes rather than standing structures, there is no obstruction to seating areas, entrances, or field visibility.

Access to Hard-to-Reach Areas

Another key advantage of rope access is its ability to reach difficult areas. Stadiums often feature architectural elements that are challenging to maintain using conventional methods, such as high roof structures, suspended signage, and intricate facades. Rope access technicians can descend vertically along stadium walls for facade cleaning, manoeuvre across large steel frameworks for structural inspections, or position themselves precisely for electrical repairs. The versatility of this technique makes it an ideal choice for a wide range of stadium maintenance tasks.

Stadium Maintenance Solutions Using Rope Access

Structural Inspections

One of the most important applications of rope access in stadium maintenance is structural inspection. Regular inspections are necessary to identify corrosion, material fatigue, and hidden defects that could compromise safety. Rope access technicians can examine steel frameworks, assess the condition of support beams, and conduct ultrasonic testing to detect internal flaws.

Cleaning and Painting

Another essential aspect of stadium maintenance is cleaning and painting. Over time, stadiums accumulate dust, dirt, and environmental pollutants that can degrade their appearance and structural integrity. Rope access allows technicians to clean large glass panels, metal cladding, and concrete facades with precision. In addition, protective coatings and anti-corrosion treatments can be applied to steel structures to prolong their lifespan.

Roof and Gutter Maintenance

Maintaining stadium roofs and gutters is crucial for preventing leaks and water damage. Rope access enables technicians to perform gutter cleaning, ensuring proper drainage and reducing the risk of flooding. It also allows for targeted roof repairs, such as sealing leaks, replacing damaged panels, and securing loose components.

Lighting and Electrical Work

Lighting and electrical maintenance are also made easier with rope access. Many stadiums rely on high-mounted floodlights and electronic displays, which require periodic bulb replacement and fixture repairs. Rope access provides a safe and efficient way to perform these tasks, as well as to inspect electrical wiring and identify potential faults.

Bird and Pest Control

Additionally, stadiums often struggle with bird and pest control. Large structures attract birds, which can create hygiene issues and damage equipment. Rope access technicians can install deterrents, such as netting and spikes, to prevent nesting in sensitive areas. They can also remove bird droppings and debris from ledges, ensuring that seating areas and walkways remain clean.

Request a Free Consultation with Dangle Rope Access Today

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help!