Sustainable Maintenance

Sustainable Maintenance Solutions: The Role of Rope Access Services in Reaching Net Zero

As the UK accelerates its journey toward a net zero carbon future, industries are being challenged to reduce emissions, improve energy efficiency, and adopt environmentally responsible practices. One area seeing a rapid transformation is building and infrastructure maintenance—an essential but often overlooked contributor to a company's overall environmental footprint.

At Dangle, we believe that sustainable maintenance is not only possible but essential. Our expertise in rope access services is helping businesses across the UK meet their sustainability goals without compromising safety, efficiency, or quality. In this article, we explore how rope access supports sustainable maintenance and contributes to the broader mission of achieving net zero.

What is Sustainable Maintenance?

Sustainable maintenance refers to the upkeep and servicing of buildings, structures, and equipment in a way that minimises environmental impact. This includes reducing carbon emissions, lowering energy and material use, avoiding pollution, and preserving natural resources—all while ensuring assets remain safe, operational, and compliant.

Traditional maintenance methods, such as scaffolding or powered access platforms, often involve high carbon emissions, excessive material use, and longer project timelines. Sustainable maintenance focuses on efficiency, adaptability, and innovation, favouring methods that reduce resource consumption and environmental disruption.

The Urgency of Net Zero in the UK

In 2019, the UK became the first major economy to pass a law requiring net zero greenhouse gas emissions by 2050. This means balancing the amount of greenhouse gases emitted with the amount removed from the atmosphere. For businesses, especially those in construction, energy, facilities management, and infrastructure, this goal presents both a challenge and an opportunity.

Meeting net zero targets requires rethinking every aspect of operations, including how structures are maintained. Maintenance can no longer be seen as a routine operational cost—it must be viewed as a strategic lever for environmental performance. That’s where our rope access services come in.

What Are Rope Access Services?

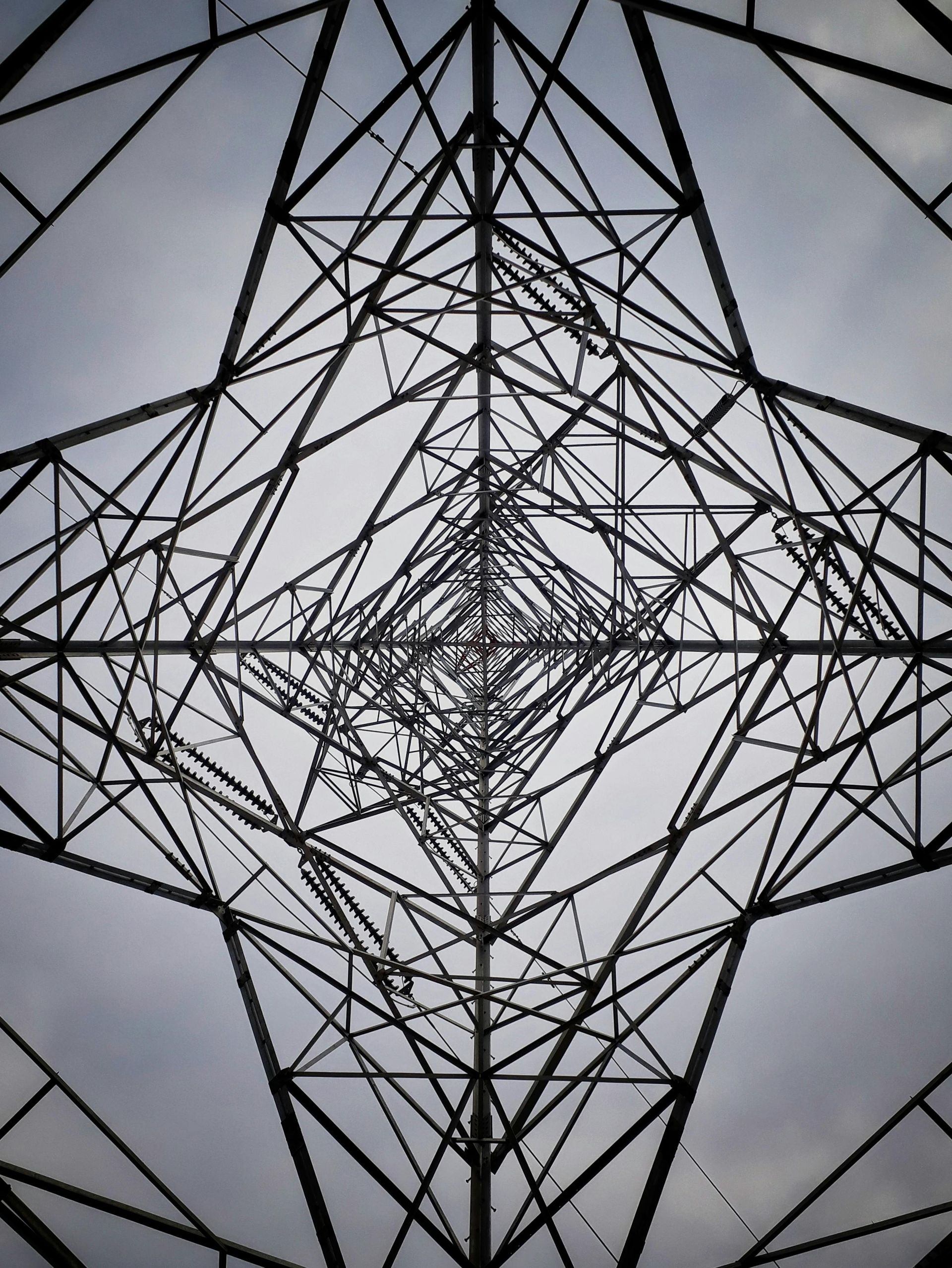

Industrial rope access is a method of working at height or in difficult-to-access areas using specialist rope and harness systems. Developed from climbing and caving techniques and refined under strict safety protocols (such as IRATA standards), rope access allows trained technicians to carry out inspections, repairs, cleaning, painting, and installations without the need for scaffolding or heavy machinery.

From high-rise buildings and bridges to offshore wind turbines and historic landmarks, rope access offers a versatile, low-impact solution for sustainable maintenance.

Why Rope Access is the Smart Choice for Sustainable Maintenance

- Minimal Equipment, Minimal Emissions

One of the core advantages of rope access is its low carbon footprint. Unlike scaffolding or powered access platforms, rope access requires no large-scale transport, diesel-powered machinery, or extensive steel structures. This drastically reduces fuel use, manufacturing impact, and transportation emissions.

Rope access teams arrive with compact gear, which is typically reusable and has a lower environmental impact over its lifespan. This makes rope access an ideal option for organisations aiming to implement sustainable maintenance practices.

- Faster Project Timelines = Reduced Energy Use

Time is energy—literally. The longer a project runs, the more energy is used on site in the form of electricity, lighting, fuel, and even extended equipment hire. Rope access allows for quicker setup and takedown, and jobs can often be completed in less time than traditional access methods.

For example, painting a façade or conducting a leak inspection via scaffolding could take several days just to set up. With rope access, the same work can often be started—and finished—within a single day, reducing the project's overall carbon footprint.

- Less Disruption to the Environment and Operations

Sustainable maintenance also means reducing the indirect environmental impact of a job. Erecting scaffolding or deploying mobile platforms can disrupt foot traffic, business operations, roadways, and natural habitats. This is especially important in urban areas, on transport infrastructure, or at protected sites.

Rope access causes minimal ground-level disturbance. This makes it a particularly sustainable solution for:

- Eco-sensitive locations (e.g. nature reserves, coastal cliffs)

- Busy commercial or urban zones

- Operating industrial plants or refineries

- Remote energy installations

- Offshore, coastal access and work over water

- Waste Reduction and Reusability

Sustainability isn’t just about carbon—it’s also about waste reduction. Scaffolding projects often generate significant waste, from single-use materials to packaging and cut-offs. In contrast, rope access equipment is compact, reusable, and maintained under strict inspection cycles according to LOLER.

At Dangle, we operate under rigorous safety and sustainability protocols, ensuring that all rope access gear is maintained, reused, and disposed of responsibly at the end of its lifecycle.

Rope Access in Support of Renewable Energy

One of the fastest-growing sectors where rope access plays a critical role in sustainable maintenance is renewable energy. Wind turbines, both onshore and offshore, require regular inspection and maintenance to ensure optimal performance and safety. Rope access is uniquely suited to this sector due to its:

- Ability to access tall, remote structures

- Minimal equipment requirements

- Weather resilience and adaptability

Our teams at Dangle have worked extensively across the UK’s wind farms, providing blade inspections, bolt torque checks, and surface paint repairs. These services are vital to keeping renewable energy infrastructure operational and efficient, directly supporting the UK’s net zero ambitions.

How Rope Access Aligns with Corporate ESG Goals

Environmental, Social and Governance (ESG) principles are increasingly guiding how organisations operate and how stakeholders—from investors to customers—assess their long-term value. Companies are under mounting pressure to demonstrate that they are reducing harm, creating positive social impact, and managing operations ethically and transparently.

Rope access supports ESG objectives on all three fronts, making it a strategic choice for companies seeking to enhance sustainability and resilience while maintaining critical infrastructure.

Environmental Impact (E): Lower Carbon, Less Waste, Smaller Footprint

Sustainable maintenance is central to the environmental component of ESG. Rope access reduces emissions and resource use across every stage of a maintenance project:

- Reduced carbon footprint: With no need for scaffolding trucks, cranes, or diesel-powered machinery, rope access teams generate significantly fewer greenhouse gas emissions.

- Minimal material waste: Rope systems are compact, durable, and reusable, generating less site waste compared to single-use materials and scaffold off-cuts.

- Lower energy consumption: Faster setup and project completion reduce on-site power and fuel use, from lighting to equipment hire.

- Minimal environmental disturbance: Because rope access requires little or no ground-level equipment, it causes less disruption to wildlife, green spaces, or public areas.

Social Responsibility (S): Safer Workforces, Smarter Communities

The social pillar of ESG focuses on how companies treat their people, support communities, and ensure the well-being of all stakeholders. Rope access contributes positively in several ways:

- Exceptional safety standards: Under IRATA guidelines, rope access maintains one of the lowest incident rates in the work-at-height industry.

- Skilled employment: Rope access technicians undergo a rigorous training and certification path, often progressing through multiple levels of expertise. This supports professional development and career growth.

- Less disruption to local communities: Unlike scaffolding, rope access doesn’t require street closures, excessive noise, or large on-site teams—making it ideal for urban, residential, or heritage environments.

- Accessibility to remote areas: Rope access allows for maintenance in hard-to-reach or isolated places (e.g. offshore installations or mountainous infrastructure), ensuring no site is left behind due to logistical complexity.

Governance (G): Transparency, Compliance, and Ethical Standards

Governance in ESG relates to how a business is run—its transparency, regulatory compliance, and risk management. Rope access supports good governance through:

- Regulated practices: Rope access is governed by internationally recognised bodies, such as IRATA, which require member companies to follow strict operating procedures, ethical standards, and audit processes.

- Clear documentation and traceability: Maintenance work carried out via rope access is fully reportable, with detailed inspection logs, photographic evidence, and real-time reporting systems—ensuring accountability.

- Reduced legal and reputational risk: By opting for a safer, less invasive form of access, companies reduce the likelihood of accidents, delays, insurance claims, or fines due to environmental disruption.

- Sustainable procurement: Partnering with rope access providers who use eco-conscious practices, ethical labour policies, and proper waste management contributes to responsible supply chain governance.

By integrating rope access into their operations, companies can meaningfully advance their ESG performance, meet compliance requirements, and satisfy the expectations of regulators, investors, and the public.

Rope Access in Heritage and Conservation Work

Preserving the UK’s historic buildings and monuments often presents unique challenges. Traditional methods can risk damaging delicate stonework, require intrusive scaffolding, or violate conservation policies.

Rope access offers a non-invasive alternative. Our technicians can carry out conservation cleaning, masonry inspections, and gutter maintenance with precision—without impacting the integrity of historic architecture. In these cases, sustainable maintenance also means preserving cultural heritage for future generations.

Learn More About Dangle Rope Access Today

Here at Dangle, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland, Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading rope access company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

To find out more about how our team can help you

contact us today. Our friendly, professional and helpful team is always on hand to help!

Overcoming Myths About Rope Access

Despite its growing adoption across a wide range of industries, rope access is still surrounded by misconceptions. These myths can cause businesses to overlook one of the safest, most efficient, and most sustainable maintenance solutions available today. Let’s clear up some of the most common misunderstandings:

Myth 1: “Rope access is only suitable for simple jobs.”

Reality: Rope access now enables complex, technical work like welding, non-destructive testing, mechanical repairs, and façade engineering to name a few. It’s used in high-risk industries where safety and precision is critical.

Myth 2: “Rope access is less safe than scaffolding.”

Reality: Rope access boasts one of the best safety records in the access industry across the globe, due to rigorous IRATA standards, double-rope systems, and comprehensive technician training and refresher training.

Myth 3: “Roped access is not a viable long-term strategy.”

Reality: Rope access is used in planned preventative maintenance across sectors like renewables, transport, and property—offering an efficient, long-term solution. It also has many advantages in reactive maintenance due to its rapid deployment.

Myth 4: “Abseiling is more expensive.”

Reality: Industrial rope access abseiling projects are often more cost-effective when you consider setup time, reduced disruption, no scaffold hire, and quicker turnaround.

Myth 5: “It’s only a niche method of access.”

Reality: Rope access is mainstream in industries that value efficiency, safety, and sustainability. Its role is only growing as businesses adopt greener practices, with commercial and residental property getting taller in major cities.