Lattice Tower Maintenance

Lattice Tower Maintenance: A Complete Guide to Safety, and Best Practices

Lattice towers are the unsung heroes of our modern infrastructure—supporting everything from telecommunications and broadcast signals to power transmission. Ensuring these towering structures remain functional, safe, and compliant requires meticulous attention to detail and industry expertise. This is where lattice tower maintenance becomes not just important, but essential.

Whether you’re managing a rural transmission mast or an iconic city landmark, this comprehensive guide covers everything you need to know about effective lattice tower maintenance and management.

What is a Lattice Tower?

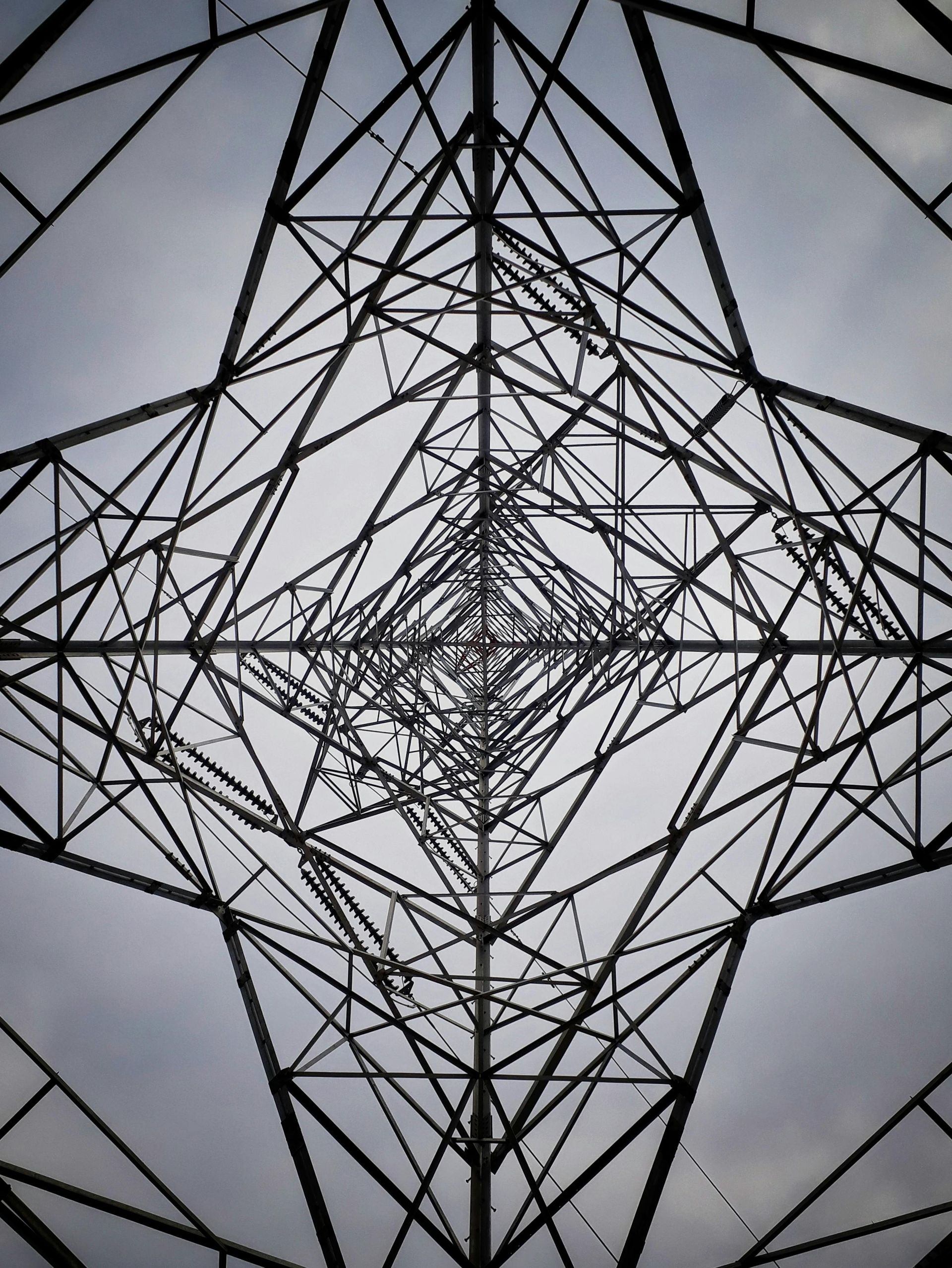

A lattice tower is a freestanding framework structure built from steel or aluminium. Designed in a criss-cross (lattice) pattern, it combines strength and stability with relatively low material use. These towers are common in:

- Telecommunication networks

- TV and radio broadcasting

- Electrical transmission

- Wind energy monitoring

- Meteorological stations

The key benefit of lattice towers is their ability to withstand extreme weather while bearing heavy loads at great heights. This makes them both efficient and cost-effective for a variety of industries.

Iconic Lattice Towers: Engineering Feats Worth Noting

Lattice towers come in various shapes and sizes, and some have become internationally recognised landmarks:

• The Eiffel Tower (Paris, France): Perhaps the most famous lattice tower in the world, standing at 300 metres tall, constructed of iron latticework in 1889. While primarily a tourist attraction, it also houses communication antennas at its peak.

• Tokyo Tower (Tokyo, Japan): Standing at 332.9 metres, this red and white lattice tower is a key broadcasting structure and a symbol of Japan’s post-war rebirth.

• Emley Moor Mast (West Yorkshire, England): While primarily a concrete structure, its predecessor was a steel lattice tower that collapsed in 1969 due to ice accumulation—a key reminder of the importance of robust lattice tower maintenance and structural integrity.

Why Lattice Tower Maintenance Matters

The structural complexity and height of lattice towers mean that any lapse in inspection, repair, or compliance can have catastrophic consequences.

Regular lattice tower maintenance ensures:

- Operational continuity (preventing downtime in communications or power)

- Safety for workers and the public

- Compliance with national and international standards

- Extended service life of the tower

- Early identification of corrosion, fatigue or wear

With strict health and safety legislation in the UK and Ireland, failure to implement a proactive lattice tower maintenance strategy can lead to fines, litigation, and reputational damage.

Key Elements of Lattice Tower Maintenance

Routine Inspection Protocols

Inspections are the backbone of effective lattice tower maintenance. Guidance to follow should include;

- BS EN ISO 1461 (galvanised steelwork)

- BS EN 1993 (Eurocode for steel structures)

- LOLER (Lifting Operations and Lifting Equipment Regulations 1998)

- PUWER (Provision and Use of Work Equipment Regulations 1998)

Types of inspections include:

- Visual inspections: Surface checks for rust, deformation, or missing bolts

- Detailed structural analysis: Using rope access to reach all points of the tower

- Non-destructive testing (NDT): Ultrasonic or magnetic testing for internal faults

- Drone surveys: Useful for initial assessments, though less effective than rope access for close-up analysis.

Corrosion Prevention and Treatment

Lattice towers are exposed to harsh environments—rain, salt, UV radiation, and temperature changes. Galvanised coatings can deteriorate over time, so corrosion control is vital.

Best practices include:

- Re-coating with protective paint systems (following

ISO 12944)

- Replacing rusted components

- Applying sacrificial anodes in marine environments

- Monitoring for galvanic corrosion between dissimilar metals

Preventative lattice tower maintenance focused on corrosion extends lifespan and enhances safety.

Bolt Torque and Structural Integrity

Loose or over-torqued bolts can compromise a tower’s load-bearing capacity. Using calibrated torque wrenches and following the manufacturer’s specifications is essential.

Checks should include:

- Torque tests at every major joint

- Replacement of degraded fasteners

- Inspection of load-bearing nodes and connections

Fall Protection and Access Systems

While rope access is ideal for flexible, low-impact inspections, permanent access systems like vertical ladders, step bolts, or platforms must also be inspected and maintained.

Maintenance should involve:

- Load testing of fall arrest systems

- Replacing worn harness anchor points

- Verifying ladder rung integrity

- Ensuring compliance with EN 365:2004 for PPE

Lightning Protection and Grounding

Given their height, lattice towers are prone to lightning strikes. A robust earthing system can prevent damage to electronic systems and minimise fire risk.

Ensure:

- Ground resistance measurements are within acceptable limits (typically <10 ohms)

- Copper conductors are intact and corrosion-free

- Surge protection devices are regularly replaced or tested

Vegetation and Site Access Control

Overgrown vegetation can obstruct access and increase fire risk. Site access and vegetation control should be part of every lattice tower maintenance plan. Key actions include:

- Regular bush clearance and tree trimming

- Foundation inspections for root or water damage

- Drainage maintenance around the tower base

- Clear vehicle and foot access routes

- CCTV or fencing free from vegetation obstructions

Routine site clearance helps protect the base structure and enables faster emergency response.

Why Rope Access is the Smarter Choice for Lattice Tower Maintenance

Rope access offers unmatched advantages for maintaining lattice towers—combining safety, efficiency, and flexibility. Here’s why it’s the preferred method:

- Exceptional Safety

Backed by IRATA standards rope access has one of the best safety records in the industry, with dual-rope systems and rigorous technician training ensuring full compliance and control at height.

- Minimal Disruption

With no need for scaffolding or cranes, rope access allows for fast deployment, making it ideal for remote, high-traffic, or environmentally sensitive locations.

- Cost-Effective

Lower equipment and labour costs mean rope access delivers high-quality lattice tower maintenance without the expense of traditional access methods.

- Versatile and Precise Access

Technicians can easily navigate complex lattice structures—reaching every bolt, beam, and joint for thorough inspections and repairs.

- Efficient for Inspection and Repairs

Rope access supports a wide range of maintenance tasks including visual inspections, NDT, bolt torque checks, corrosion treatment, and equipment installation.

- Built-In Emergency Response

Rope access teams are trained in high-angle rescue, ensuring immediate and safe evacuation in case of incident—meeting all safety regulations.

- Environmentally Friendly

With a low carbon footprint, reduced site impact, and reusable gear, rope access is the sustainable maintenance choice for modern lattice tower management.

Lattice Tower Risk Management

Each tower has a unique set of risks depending on its location, use, and age. A comprehensive risk management plan is critical to maintaining safety, performance, and legal compliance.

Environmental Risks

- Wind and ice loading: Can strain or collapse structures

- Salt air corrosion: Especially near coastal zones

- Lightning strikes: Require tested and functional earthing systems

Mitigation: Site-specific inspection intervals, protective coatings, and environmental monitoring tools.

Structural Risks

- Material fatigue from cyclic loading and ageing

- Overloaded or poorly maintained connections

- Unapproved modifications compromising design integrity

Mitigation: Qualified inspections, structural engineering reviews, bolt torque checks, and NDT testing.

Operational and Access Risks

- Untrained personnel leading to safety violations

- Improper PPE or access systems

- Accidents during high-level maintenance work

Mitigation: Rope access teams with IRATA certification, scheduled PPE inspections, and rescue planning.

Compliance and Legal Risks

• Non-compliance with HSE, LOLER, PUWER, and BS/EN standards can lead to legal consequences, insurance issues, and site shutdowns.

Mitigation: Maintain detailed inspection logs, conduct regular audits, and use certified equipment and personnel.

Managing these risks ensures that your lattice tower maintenance plan is both effective and future-proof.

Sustainability in Lattice Tower Management

As ESG (Environmental, Social, and Governance) standards rise, companies are being held to higher accountability. Sustainable lattice tower maintenance includes:

- Using biodegradable lubricants

- Minimising vehicle emissions

- Recycling removed components

- Planning maintenance to reduce energy disruptions

By adopting sustainable rope access methods, you’re contributing to greener infrastructure management—while maintaining high safety and performance standards.

Learn More About Dangle Rope Access Today

Here at Dangle, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland,Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading rope access company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help!