Railway Inspection

Railway Inspection & Rope Access: A Smarter Way to Maintain Rail Infrastructure

The railways in the UK play a crucial role in the national infrastructure, encompassing thousands of miles of track, tunnels, bridges, and embankments that necessitate consistent maintenance. With the increasing demand for efficiency, safety, and economical solutions, railway inspection techniques are advancing — with rope access at the forefront of this evolution.

Recently, headlines in the news, underline the urgency and scale of this evolution. For example, Network rail has invested up to £1.1 billion for on-track maintenance machinery, reflective of the growing national focus on infrastructure renewal and technological advancement

Traditionally, a railway inspection relied on scaffolding, MEWPs (Mobile Elevated Work Platforms), and even complete line closures to reach critical components of the rail network. While these approaches may be effective, they’re often time-consuming, expensive, and highly disruptive. In contrast, rope access provides a modern alternative: it’s faster, safer, and far more adaptable.

At Dangle, we specialise in using rope access to carry out complex inspections across the rail sector. This blog explores how rope access is changing the game, the specific benefits for railway inspection, and why it’s the smart choice for operators looking to keep their infrastructure running smoothly.

The Importance of Railway Inspection

Railway inspection plays a pivotal role in ensuring the safety, functionality, and long-term reliability of the rail network. The infrastructure is subject to constant stress from dynamic loads, environmental exposure, weather extremes, and ageing components. Without regular and detailed inspections, minor defects can go undetected and escalate into major failures.

The key purposes of railway inspection include:

• Ensuring Passenger Safety

• Preventing Service Disruption

• Complying with Regulations

• Informing Asset Management

• Reducing Long-Term Costs

Given the age of much of the UK’s railway infrastructure, inspections are not just routine — they’re essential.

In today’s context of ageing infrastructure and growing passenger numbers, railway inspections must evolve to become more predictive and data-driven. With greater scrutiny on public safety and performance, the frequency and scope of inspections are increasing. Railway companies are moving towards condition-based and risk-based inspection strategies that focus resources where they’re needed most, reducing waste and improving outcomes.

Applications of Rope Access in a Railway Inspection

According to Rail Industry Connect, 2025 is seen as a transformative year for the UK rail sector with increased focus on predictive maintenance, decarbonisation and digital innovation. As the UK rail network undergoes structural and operational changes - including the recent re-nationalisation of South Western Railway - there is increasing pressure to deliver maintenance more efficiently and transparently. Rope access plays a vital role in supporting this transition, offering a versatile and cost-effective solution for railway inspection and maintenance.

Rope access is highly versatile and can be used across nearly all components of a railway inspection. Here are some of the key applications:

Bridge Inspections

Railway bridges — many of which are over a century old — require regular detailed bridge inspections. These often involve:

• Visual and photographic surveys

• Steel thickness measurements

• Corrosion and fatigue assessments

• NDT (non-destructive testing) techniques

Rope access allows technicians to reach all areas of a bridge without the need for extensive scaffolding or rail closures.

Tunnel Examinations

Tunnels require frequent inspection to identify water ingress, structural cracking, and deterioration of linings. Rope access is ideal for:

• Shaft inspections

• Overhead arch surveys

• Detailed mapping of defects

In confined environments where space is limited, rope access teams can work safely without large equipment.

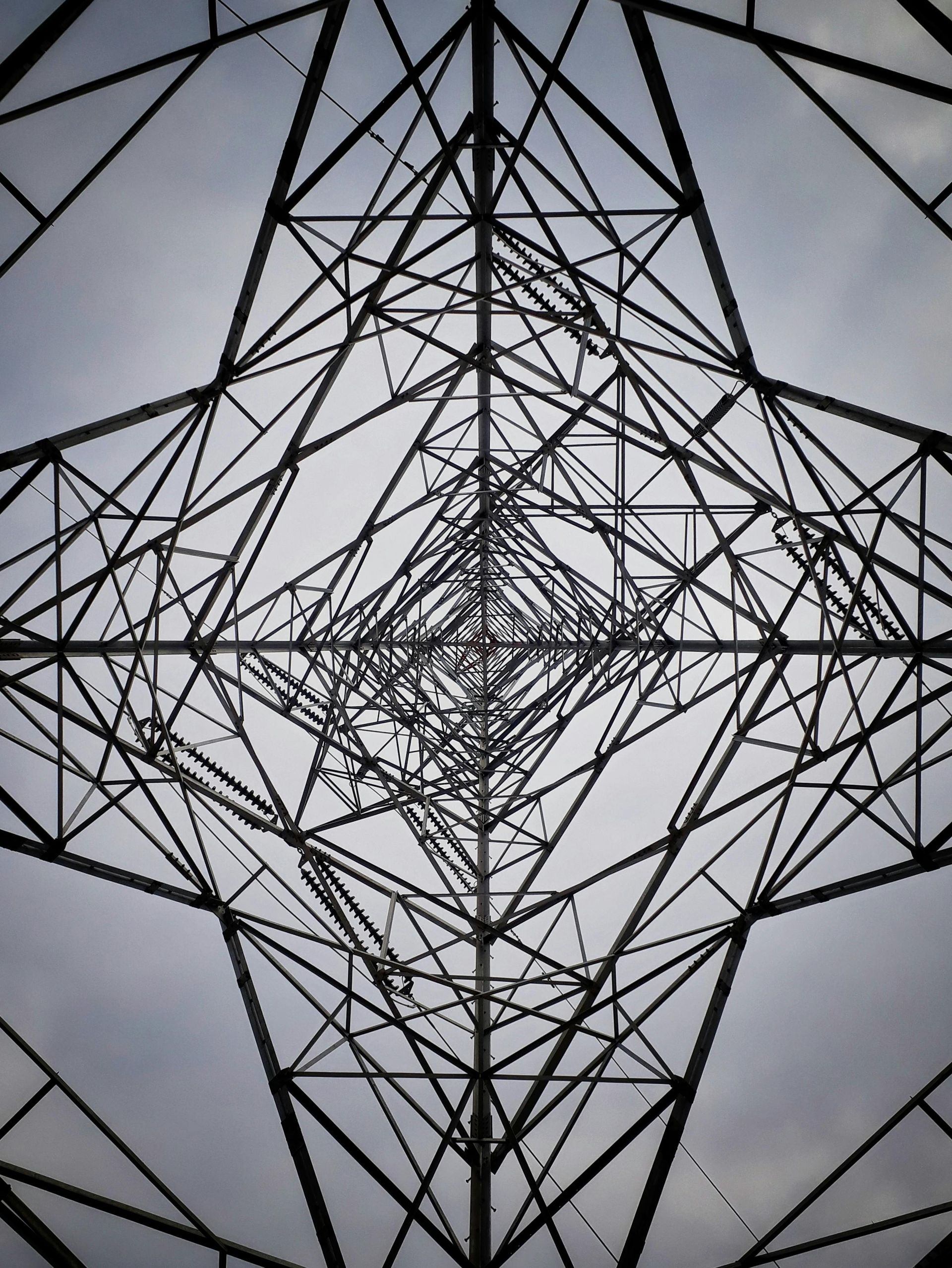

Signal Gantry and OLE Inspections

Signal gantries, overhead line equipment (OLE), masts, and support structures must be inspected for corrosion, fatigue, and component integrity. Rope access enables:

• Swift access to high-level components

• Checks on bolts, welds, and brackets

• Electrical and mechanical inspections without interference to signalling systems

Embankments and Drainage Surveys

Embankments and cuttings are vulnerable to erosion, slippage, and water damage. Rope access can be used to:

• Survey steep slopes

• Perform core sampling and vegetation clearance

• Assess and maintain drainage channels

Cliff Stabilisation and Slope Protection

Certain sections of the UK rail network, particularly along coastal or upland routes, run directly beneath cliffs or steep geological features. These areas are prone to rockfalls, landslides, and erosion, which pose a serious threat to the railway below.

Rope access is ideal for carrying out cliff stabilisation works such as:

• Installing rock bolts, mesh netting, or geo-textiles

• Applying sprayed concrete (shotcrete)

• Conducting geological inspections and assessments

• Installing slope drainage to reduce water pressure buildup

Railway Inspection Technology Integration

At Dangle, we integrate rope access with the latest railway inspection and survey technologies to deliver more value to our clients. Our approach combines traditional climbing expertise with high-tech tools for a complete solution.

Drones provide rapid assessments of inaccessible areas, especially in preliminary or large-scale surveys.

Many defects are not visible to the naked eye. Our rope access technicians are trained to use NDT methods such as ultrasonic, magnetic particle, and dye penetrant testing.

Protective coatings are an essential part of railway infrastructure maintenance, helping to prevent corrosion and extend the service life of critical assets. As part of comprehensive railway inspection programmes, industrial painting ensures that structures like steel bridges signal gantries, and overhead line supports remain in safe working condition.

Rope access allows our technicians to carry out industrial painting tasks in tandem with railway inspection activities, especially in areas that are difficult to reach using traditional access methods. This combined approach improves efficiency, reduces operational downtime, and supports long-term asset management.

Traditional Access vs Rope Access: A Comparative Overview for Railway Inspection

| Feature | Scaffolding | MEWPs | Rope Accss |

|---|---|---|---|

| Set up Time | High | Medium | Very Low |

| Operational Disruption | High | Medium | Very Low |

| Cost | High | Moderate to High | Low to Moderate |

| Accessibility | Fixed Points Only | Limited surfaces | Almost Unlimited |

| Environmental Impact | High | Medium | Very Low |

| Flexibility | Low | Moderate | High |

| Mobility on site | Fixed | Limited | Excellent |

Learn More About Dangle Rope Access Today

Here at Dangle, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland,Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading rope access company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help!