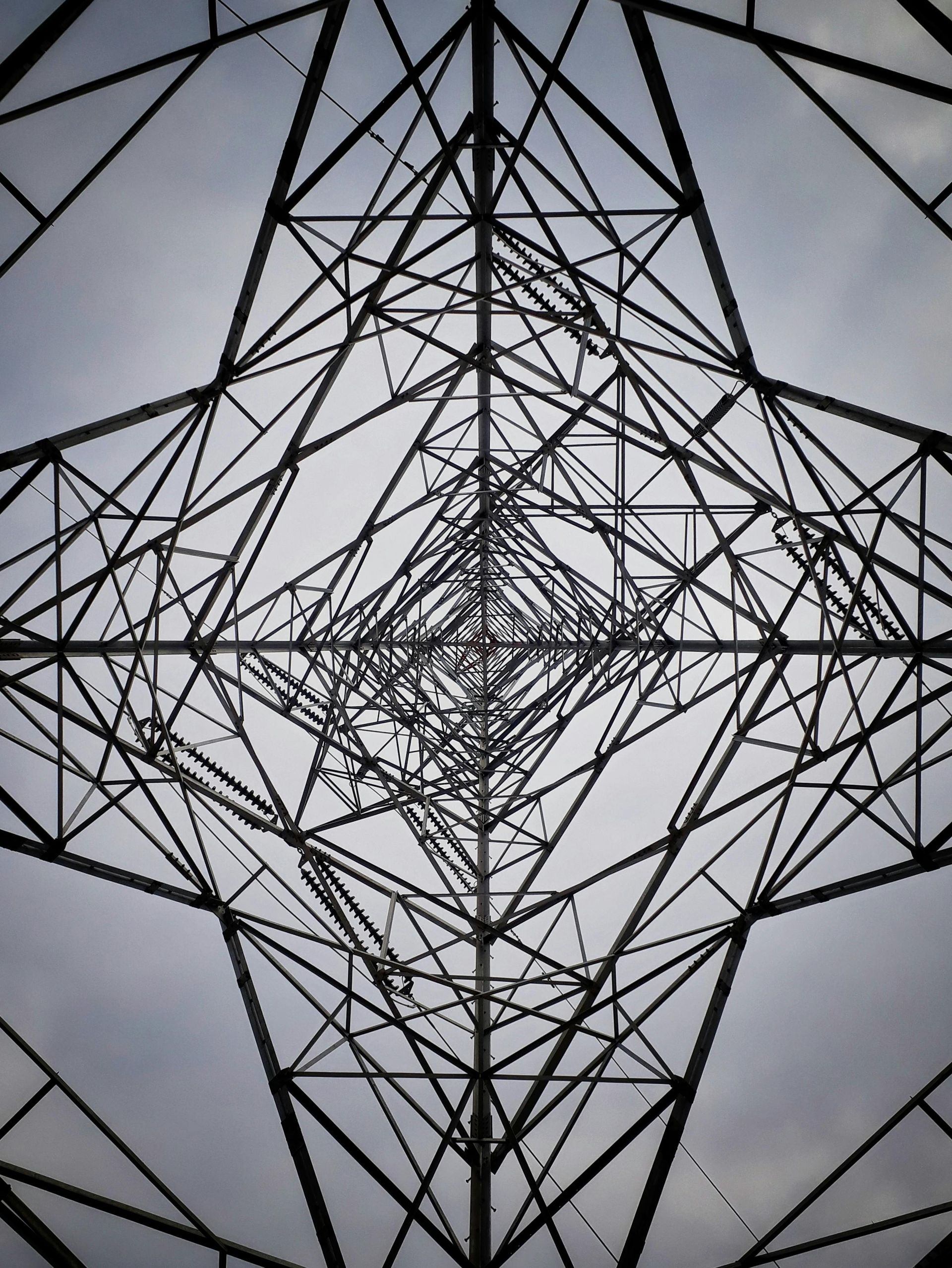

Offshore Wind Farm Coating Surveys

Rope Access Wind Farm Coating Inspection

Wind Farm Paint Inspection

This blog post aims to supply our Clients and Coating Inspection personnel with a detailed procedure for conducting a Visual Inspection (VI).

The procedure covers the following aspects:

- General Visual Inspection (GVI) conducted from a distance greater than 1 meter from the component being tested.

- Close Visual Inspection (CVI) of painting, performed within 1 meter of the component, using unaided vision.

- Enhanced Visual Inspection employing optical aids, including magnifiers, microscopes, mirrors, borescopes, endoscopes, digital cameras, and more.

RUST DEFINITIONS

- Corrosion: The wearing away or gradual destruction from the surface inward due to either chemical attack or oxidation.

- Rusting: Oxidation of iron. This is the most common form of corrosion on facilities and may result from the breakdown of protective coatings.

- Scale: Build up of a layer of corrosion product that is of measurable thickness and completely covers the base material underneath it. The thickness of scale is some magnitude greater than the material loss below it. The scale may be loose or adherent, however is generally easily removed in order to sight the extent of the material loss underneath. This is generally a result of extreme oxidation on steel structures.

- Pitting: Depressions in the surface as a result of material loss, either separate or confluent. Little or no corrosion product may be evident.

- Coating Inspection: A covering applied to the surface of a object or structure, usually referred to as the substrate with inspection being most generally, an organised examination or formal evaluation exercise, usually involving measurements, tests and procedures.

COATING QUALIFICATIONS

Personnel using this procedure should be trained and competent:-

Personnel should have been examined in the preceding twelve months by a competent medical authority to prove:-

- a natural or corrected near vision acuity in at least one eye such that they are able to read Jaeger No.1 Times Roman (N4.5 Sized) or equivalent letters on a Jaeger standard test chart at a distance of not less than 300mm.

- a natural or corrected distance acuity of not less than 20/40.

In addition to any formal qualifications (usually NACE , ICORR , BGAS and FROSIO as the most recognised bodies in the world of painting inspection certification) personnel should be trained in the correct usage of any specialised equipment (for example low and high voltage holiday detection), such training should be based on manufacturers recommendations and guidelines.

SAFETY REQUIREMENTS FOR COATING INSPECTORS

It is of paramount importance to assess all hazards associated with a inspection operation and take steps to ensure that the risk of accident / injury from those hazards are removed or reduced to an acceptable level. Many precautions are common sense but it is important to consider the following;

- Access and egress to the area.

- Atmospheric conditions ( Temperature , humidity etc )

- Electrical hazards associated with light sources ,hand tools etc

- The hazards associated with any particular surface cleaning agents i.e. paint strippers, solvents detergents etc.

Dangle Rope Access will always preform a dynamic risk assessment prior to commencing any work scope, no matter how large or small.

PAINT INSPECTION EQUIPMENT

Specialised equipment utilised to enhance Visual Inspections should be subject to test/examination/ calibration and certification in accordance with manufacturers recommendations or guidelines, all of which Dangle can supply using our own in-house paint inspection test equipment, all manufactured by the world leaders in paint inspection test equipment Elcometer .

Paint Inspector Requirements

Prior to examination the Coating or Paint Inspector should ensure familiarity with the manufacturing and finishing processes involved in producing the material/item to be examined .

Surface Condition and Preparation

The area under examination must be free from surface contaminants that may reduce the efficiency of inspection equipment, or lead to false or inaccurate readings. Typical examples of such contaminants include ; rust, scale, grease, spatter etc.

Paint coatings are not normally to be removed without the prior consent of the client.

The area under examination must be suitably illuminated preferably by natural daylight, or the artificial light must be of a sufficient level to ensure an accurate inspection. (Typically 500 lux at the point of inspection of a coating.) If artificial lighting is required the Coating Inspector must allow sufficient time for his/ her eyesight to adapt to the change in conditions prior to the inspection taking place.

GENERAL VISUAL INSPECTION (GVI)

An appropriate vantage point from which the item requested for a GVI can be easily seen. The vantage point should be chosen at a safe location i.e. from a walkway or access platforms and free from emergency routes.

It is advisable that a portable high intensity light source be taken to site to improve illumination, for most oil and gas platforms this will be required to be EX rated so that sparking potential is eliminated. The appropriate permits for this equipment should be sought and all safety requirements must be adhered to. The items selected for this type of coating inspection may then be viewed either directly or indirectly using Binoculars. Any of the following anomalies should be noted on the ‘Visual Inspection Report’ sheet provided by Dangle:

- Any impact damage causing dents or buckles

- Any significant areas of coating breakdown where corrosion is evident

- Any rust staining from nodal or other welds (may indicate weld failure)

- Any debris lodged on structural members which could damage coatings or otherwise cause corrosion

- Any loose structural cladding or passive fire protection

- Any loose or otherwise damaged pipe clamps

- Any areas where cladding or insulation may of prevented observing the underlying surface (such as Corrosion Under Insulation CUI)

If an observed defect appears to be of a serious nature, then a closer investigation perhaps using rope access techniques should be initiated, at a minimum documented and reported.

If any further NDT techniques, such as MPI, UT or Eddy Current is required to be performed the results of this should be recorded on the appropriate Inspection Report and this should be attached to and referenced on the ‘Visual Inspection Report’ creating a document trail.

The material should be subject to thorough visual examination taking into account surface abrasions, corrosion, erosion, mechanical damage, wear and tear, distortion and poor workmanship which can include, although is not limited to, sags, runs, misses etc. All indications must be assessed in accordance with the acceptance levels detailed within the Clients reference Specification or Inspection Test Plan (ITP). The Clients Representative should be notified of all indications that are determined as being out-with their acceptance criteria specified following the examination, on an ascending scale of severity, with serious/dangerous anomalies being highlighted immediately and less severe non-safety critical items being reported within the project duration. It's always important to consider the clients representative may not have any formal coating inspection knowledge.

CLOSE VISUAL INSPECTION (CVI)

If an anomaly is spotted during a General Visual Inspection, then a close visual inspection should be undertaken to further investigate the finding, if the task has been risk assessed and is safe to do so.

CVI will also be directed at a particular defined item or critical part of a structure e.g. a structural node, a weld or a bolted joint. The purpose of a CVI is to assess the condition of the subject and to identify and, if appropriate, measure any anomaly. A CVI will require access to be provided which allows physical contact (< 1M) with the area in question, and rope access using Dangle's expertise in coating inspection is a safe and cost effective method for this, with rapid deployment and minimal downtime, if any, caused. A Close Visual Inspection will normally require the subject part to be cleaned from any adherent deposits. The requirement for a CVI will be identified at the planning stage or, it may be initiated as a result of a possible anomaly identified by GVI.

CORROSION EXTENT QUALIFIERS

- Reference: General arrangement drawings, Asset maintenance programme, appendices for graphs of extent estimators etc.

- Extent: Isolated, scattered, localised or general

- Severity: Light, moderate, or heavy

- Type: Rusting, scaling, crack or pitting

These qualifiers are further explained and broken down in the preceding paragraphs.

CORROSION EXTENT CLASSIFICATIONS

- Isolated: This term should apply when there are only a few counted incidences of the effect to be reported, which individually do not cover any more than 5% and collectively no more than 20% of the surface area of the item being reported upon.

- Scattered: This term should apply when there are many incidences to be recorded which follow no set pattern, and which individually cover no more than 5% and collectively no more than 20% of the surface area of the item being reported upon.

- Localised: This term should apply when there are only a few incidences that follow a pattern and individually cover no more than 10%, and collectively no more than 30% of the surface area of the item being reported on.

- General: This term should apply when there are either too many incidences to count which collectively cover more than 20% of the surface area, or when there are only a few incidences which collectively cover over 50% of the surface area of the item being reported upon.

SEVERITY & RUST TYPE CLASSIFICATION

The severity and type of corrosion could be reported in accordance with the following sub-sections.

Rusting

- Light Rusting: Tarnishing or ‘flash rusting’ which leaves a loose powdery deposit. The base surface has not been unduly roughened by corrosion.

- Moderate Rusting: Corrosion of a surface has resulted in obvious material loss in some areas, leaving roughened or dimpled surface, whilst still retaining patches of the original surface locally.

- Heavy Rusting: Corrosion resulting in obvious material loss, the surface having been roughened or dimpled with no areas of the original surface remaining.

Scaling

- Light Scale: A single layer of corrosion product, less than measurable thickness.

- Moderate Scale: A single layer of corrosive product less than 1mm thick, either adhering to, or flaking away from the surface

- Heavy Scale: Multiple layers of corrosion product, over 1mm thick, either adhering to, or flaking away from the surface.

Pitting

- Light Pitting: The surface has been attacked in specific areas, leaving small pits of less than 1mm depth and of less than 1mm width, which are generally isolated and not extensive.

- Moderate Pitting: The surface has been attacked in specific areas leaving pits of less than 2mm depth and less than 2mm width, which are generally isolated and not extensive.

- Heavy pitting: The surface exhibits either many small pits which are generally isolated and not extensive, resulting in a break-up of the surface, or individual pits whose width and/or depth exceed 2mm.

Click here to check out our blog post of Corrosion Classifications in detail.

TYPICAL CORROSION ACCEPTANCE OR REJECTION CRITERIA?

Typically Corrosion Acceptance and Rejection criteria could be as per the Client or the Class Society Specification.

If a client has a specific anomaly reporting system, or categorising of anomalies in severity categories, then usually this system will be adopted for reporting and assessment of accept/reject during the coating project, however its imperative that this is discussed and determined.

COATING DEFECT REMOVAL & REPAIR

Defect Repairs should be re-examined utilising the same inspection methods & equipment that detected the original defect, with additional disciplines and methods being adopted as deemed a requirement.

REPORTING

A fully detailed inspection report shall be provided on completion of all Coating Visual Inspections preformed by Dangle. Typical details would include but will not be limited to ;

- Project Code

- Client

- Location

- Description of the item under examination (listing serial / ident no’s as appropriate)

- Reference to Specifications / Standards / Client Documents

- Inspection Procedure Reference

- Lighting Conditions

- Surface Condition & Cleaning methods

- Inspection Personnel Details & Qualifications

- Description of methods and equipment utilised

- Date of Inspection

- Results of examination

- Limitations & Restrictions

- Details of any anomalies (Including locations /dimensions)

- Recommendations

FEATURES THAT PROMOTE CORROSION

A number of design features promote corrosion because they immediate local environment and also because they effect some other part of the structure or electrochemical system. Some fractures are mainly applicable to structures, tanks, etc, and they can be placed in a number of fibroid groups which will be considered below;

Crevices are formed at joints where small gaps remain between the components of the joint. On the whole, good welded joints are less susceptible than bolted joints, although methods such as stick welding can cause a series of crevices.

Entrapment of Moisture salts and dirt can collect in many parts of a structure where open channels and angels can collect water which, as it evaporates, may leave concentrated salt solutions in contact with the protective coatings.

The local environment may be more corrosive than that for which the protective system was chosen to withstand, so premature coating failure occurs. Moisture can be a problem where absorbent materials such as wood or lagging material is in contact with metals, particularly steel or aluminium alloys. This can lead to serious localised corrosion. The floors of tanks, where there may be stagnant areas are particularly susceptible.

Ground Level Corrosion Problems frequently occur at ground level where steel columns enter or rest on the ground. The situation arises from the collection of water that runs from the structure and often there is a build up of debris, which acts as a poultice at the foot of the column. Furthermore, there is usually an element of splashing.

Limited Access Corrosion problems are likely to arise where access is limited or not possible without correctly trained IRATA rope access technicians, resulting in inadequate or no protective coatings in that region. Further problems are incurred as the corrosion may remain unseen and can reach serious, even critical conditions.

Shape In so far as coatings are concerned, the shape of structural members has a bearing on their performance. Rounded sections are easier to coat and less prone to damage than edges on rectangular sections. Typically a radius of >2mm for edges is good practice (ISO 08008611543 and considered rounded although always consult the criteria as per Client, IPT or the Class Society Specification.

About Dangle Rope Access

Here at Dangle, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help.