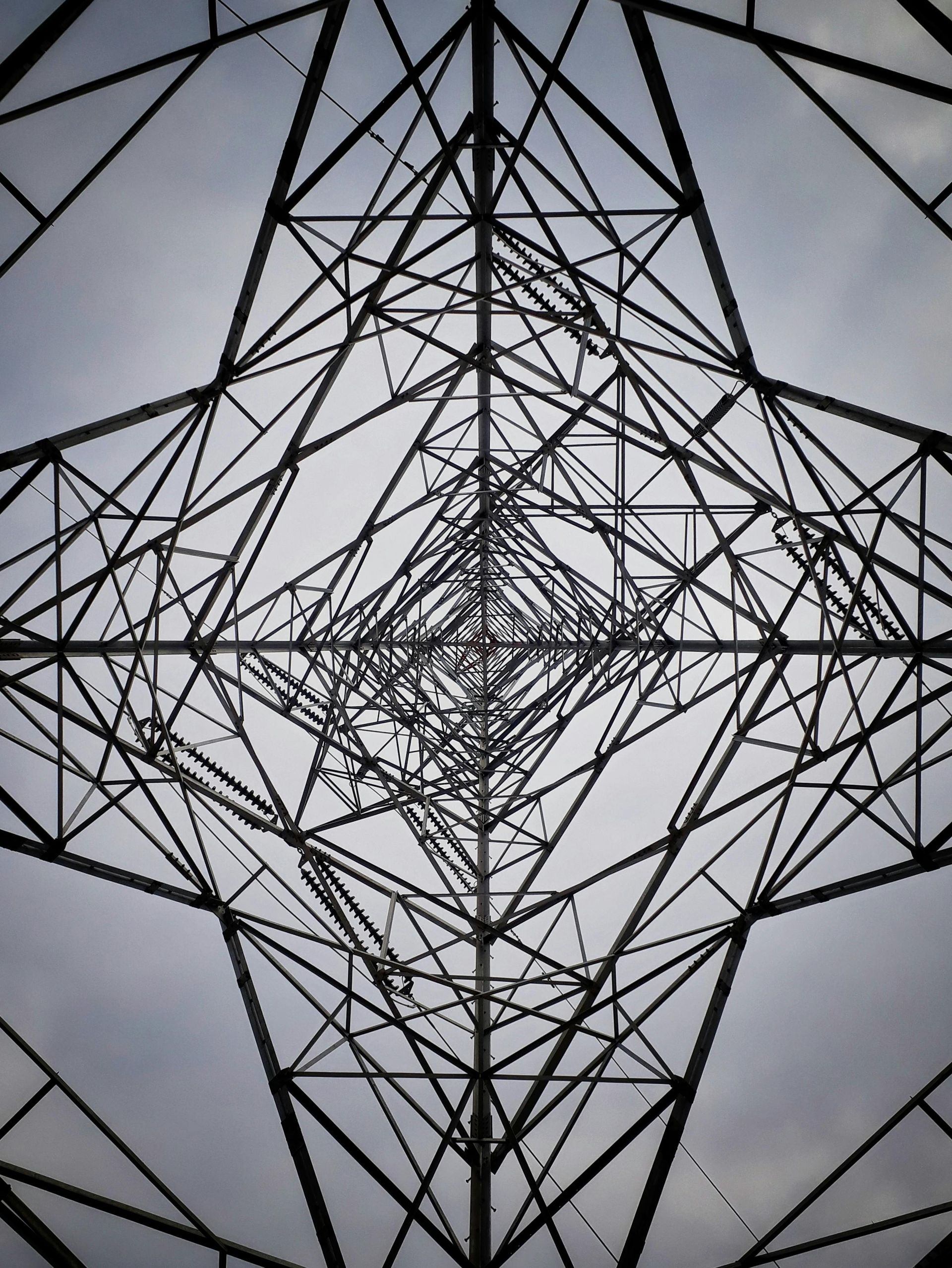

Project Case Study - Tower Coating Repairs

Offshore Rope Access Paint Repairs

Rope Access Wind Farm Painting

Here at Dangle, we have extensive experience in working on projects of all scopes and sizes, and over the years, we have consistently put our skills to the test by tackling a diverse array of rope access projects, even those of the most complex and challenging nature. Our team's expertise allows us to adapt to various circumstances and requirements, ensuring outstanding results no matter the difficulty of the task at hand.

As part of a recent project we undertook, we were specifically tasked with executing a comprehensive coating repair campaign for wind turbine tower sections that had unfortunately sustained mechanical damage during the installation phase. This situation required us to devise a post-installation access method that would leverage the skills of our specialist rope access technicians. Our goal was to ensure that the solution we provided was not only cost-effective but also minimised any disruption to our client’s day-to-day business operations, thus maintaining their productivity while we worked diligently to restore the integrity of the wind turbine structures.

Wind Farm Maintenance Solutions

After listening carefully to the project brief and our client’s requirements, Dangle mobilised a team of rope access L3's and coating technicians, that included AMPP (formally NACE) painting inspectors to the site in order to perform the paint repairs to the manufactures specification. Throughout the entire process, we used our expert knowledge of combining rope access and industrial coatings to complete the project to an extremely high standard.

A Route to Success for Wind Turbine Operators

Dangle, from mob to demob, took control of the entire coating work-scope, from liaising with Hempel A/S, preforming Lock out - Tag outs and blade pinning to documenting all the required stages of quality management. From the moment you get in touch, we go above and beyond to manage every stage of the process, to ensure every project is delivered in a timely manner and in line with your bespoke project requirements.

"Safety and feedback is what drives us to Reach the Unreachable"

If you would like to discuss any IACC (Inspection, Access, Coatings and Composite) requirements, please do not hesitate to get in touch with a member of our team.

About Dangle Rope Access

Here at Dangle, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help.